Success Story: High Efficiency Impeller Design for Wastewater Pumps through High Fidelity CFD simulations

NCC presenting the success story

Turkish National e-Science e-Infrastructure (TRUBA), operating under Turkish Academic Network and Information Center (TUBITAK ULAKBIM) is the coordinator of NCC Turkey. Middle East Technical University (METU), Sabancı University (SU), and Istanbul Technical University National Center for High-Performance Computing (UHeM) are the third parties of the NCC. While METU is a public university based in Ankara, SU is a privately-funded university in Istanbul.

ITU UHeM, also based in Istanbul, provides supercomputing and data storage services to academic and industrial users. Our competencies include High-Performance Computing (HPC), High-Performance Data Analytics (HPDA), Artificial Intelligence (AI), CUDA, Materials Science, Computational Fluid Dynamics (CFD), and several other fields. The particular third-party presenting this success story is UHeM.

Technical/scientific Challenge:

As the cost of energy increases one has to spend it more efficiently to obtain sustainability. Also, net carbon zero energy production is another aspect of sustainability. On top of these two, recycling water is becoming more and more important and hence the water treatment facilities. EYS is already a manufacturer of rugged and robust submersible manure pumps which are field proven in terms of durability.

The problem to be tackled in this case study is to reduce the hydraulic design process time and increase the accuracy of our predictions with the help of high-fidelity Computational Fluid Dynamics simulations using national resources. These high fidelity numerical simulations are conducted by using an open-source software, OpenFOAM.

Business impact:

- This result obtained via this case study shows that using HPC resources for high fidelity numerical simulations increases the accuracy of predictions for industrial applications and hence make the CFD calculations more reliable.

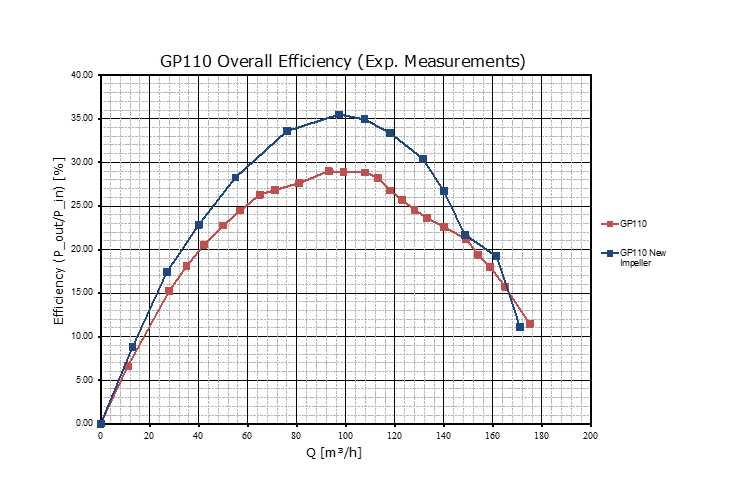

- An increase of %7 in efficiency is achieved with the new impeller as shown in Figure-2.

- This real-life result encourages us to use more HPC resources in the future and company has already applied for another national grant as a result of this study.

Figure 2: Efficiency comparison between two designs

.It is shown by the results (e.g. Figure 2) of this preliminary study that the efficiency can be improved faster by using HPC resources. The main reason is that by increasing the accuracy and reliability of the simulations, a significant improvement is achieved in decreasing the number of design iterations, shortening prototyping time and lowering the cost of model production and prototype testing.

EYS is hoping to expand their computational efforts by incorporating an advanced optimization tool in their computational design process and bringing it to a closed loop to achieve most efficient products.

The company increased their competitiveness in the market by directly increasing the efficiency of their product. EYS will be following the same path for different line of products in their wide product range.

Industrial Organisations Involved:

EYS strives to offer practical solutions to organics recycling problems by putting to use their knowledge and experience in manure management, dewatering and composting solutions. The company offers innovative and quality products to shape the future of environmental and agricultural sectors. From scrapers to pumps and mixers, separation to filtration, composting to field applications, it offers the widest range of products and models imaginable in the world of manure management.

Solution:

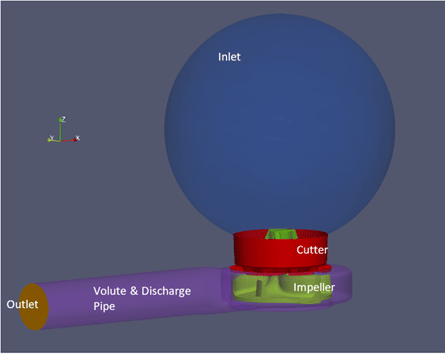

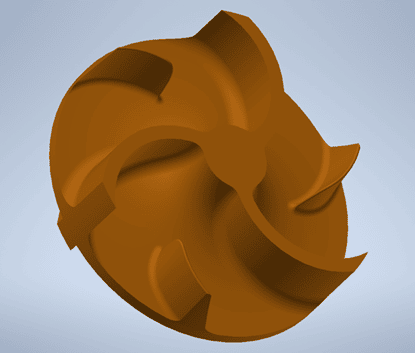

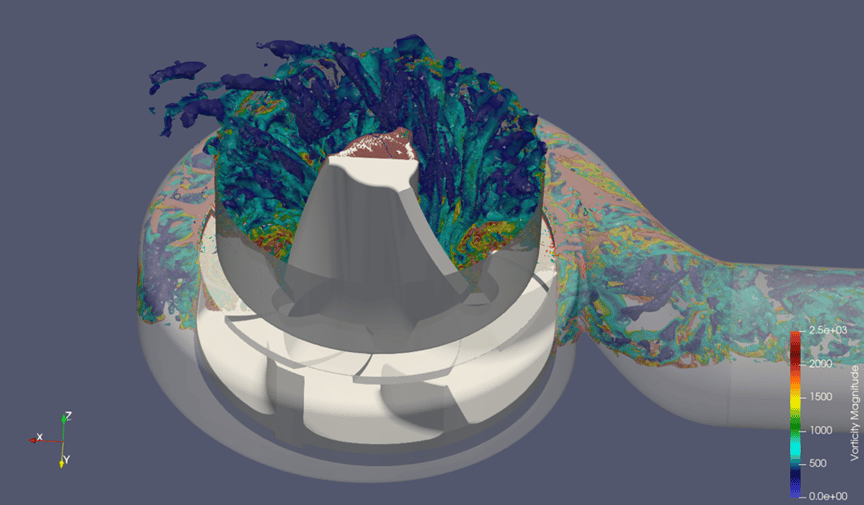

An important aspect of this project is to understand if the dynamic interaction between the rotating impeller blades and the stationary cutter channels can be captured with a reasonable amount of computational effort. Since this is a submersible pump, in order to improve the inflow characteristics a sphere is attached to the suction side. Stator and rotor regions are coupled using the cyclic arbitrary mesh interface method. The full computational domain, the impeller and instantaneous visualization of the vortical structures inside the suction cone can be seen at Figure 1.

Figure 1: Full computational domain, the impeller and vortical structures inside the suction cone.

The full flow field for the high fidelity large eddy simulation at off-design condition is discretized with 90 million cells. This high fidelity numerical simulation is performed using the computational resources provided by EuroCC@Türkiye.

Benefits:

- EYS has gained extensive experience on conducting high fidelity simulations by using HPC resources.

- EYS manufactured wastewater pump prototypes, measured performance and validated simulations.

- EYS increased hydraulic efficiency of submersible wastewater pump using geometry modifications.

SUCCESS STORY # HIGHLIGHTS:

Success story # Highlights:

- Keywords: CFD, WasteWater management, Energy Efficiency, submersible chopper pumps, rotodynamic machinery.

- Industry sector: Agriculture, Energy, Mechanical Engineering, Environment, Manufacturing & Engineering

- Technology: HPC, High Fidelity Simulations, Advanced Turbulence Modeling

Contact:

Ayse G. Gungor, ayse.gungor@itu.edu.tr

This project has received funding from the European High-Performance Computing Joint Undertaking (JU) under grant agreement No 951732. The JU receives support from the European Union’s Horizon 2020 research and innovation program and Germany, Bulgaria, Austria, Croatia, Cyprus, the Czech Republic, Denmark, Estonia, Finland, Greece, Hungary, Ireland, Italy, Lithuania, Latvia, Poland, Portugal, Romania, Slovenia, Spain, Sweden, the United Kingdom, France, the Netherlands, Belgium, Luxembourg, Slovakia, Norway, Switzerland, Turkey, Republic of North Macedonia, Iceland, Montenegro