Success Story: Computational Fluid Dynamics of Selective Catalytic Reaction

NCC presenting the success story

The Czech National Competence Centre (NCC) for High-Performance Computing (HPC) and Data Analysis (HPDA) is represented by IT4Innovations National Supercomputing Center at VSB – Technical University of Ostrava. Its mission is to analyse, implement, and coordinate all necessary activities and offer end users its services to meet their needs: from access to supercomputers and technology consulting to providing training for industry, public administration, and academia.

Industrial Organisations Involved:

The ORGREZ company provides services and supplies in several specific fields of power engineering, thermal engineering and ecology, generally in the processes of fuel energy conversion and electricity production and distribution. The Ecological Systems Division deals with greenhouse gas issues, both in terms of technologies for controlling and reducing pollutant emissions and systems for monitoring and evaluating greenhouse gas emissions, especially CO2 and NOx.

Technical/scientific Challenge:

The main objective of the proof-of-concept was to determine whether Computational Fluid Dynamics simulations could be used for the fast and efficient description of the catalysis process of the selective catalytic reduction technology (SCR), and therefore can be used as a tool for the design of this technology, which belongs to the group of DeNOx technologies used to achieve the required reduction of the concentration of nitrogen oxides (NO, NO2, N2O) in the exhaust gases of combustion plants to the required level given by the applicable emission limits of specific combustion plants.

Business impact:

Currently, the design of SCR equipment is based on experience and simplified calculations. Using numerical modelling and simulations will make the process more efficient and faster and allow subsequent optimisation of the proposed solution. The use of HPC will enable these simulations to be finished in a reasonable time.

Based on this proof-of-concept, IT4Innovations and Orgrez have submitted a joint project to develop software for the efficient evaluation of catalytic processes and comprehensive support in designing SCR technologies for industrial applications. This project has been supported by the Ministry of Industry and Trade and will be implemented over the next 18 months.

The knowledge gained from this proof-of-concept will be fully used in this follow-up project. In addition to numerical modelling and HPC, the algorithms and methods of artificial intelligence will be used to develop the software tool mentioned above.

Solution:

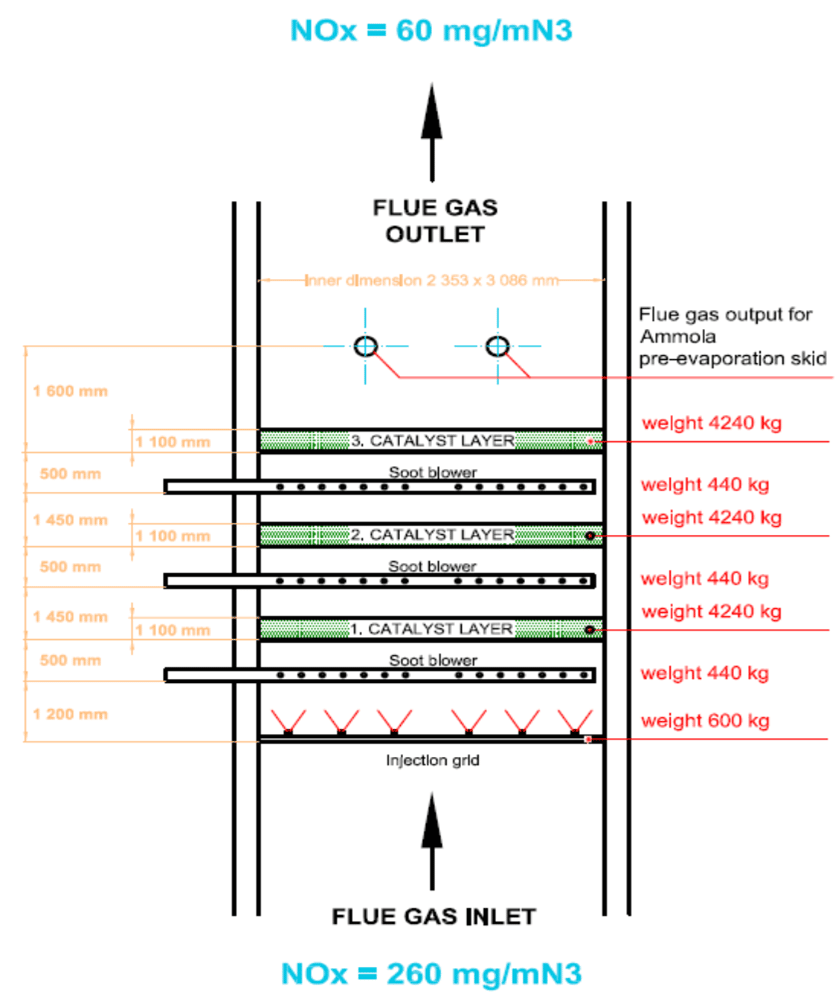

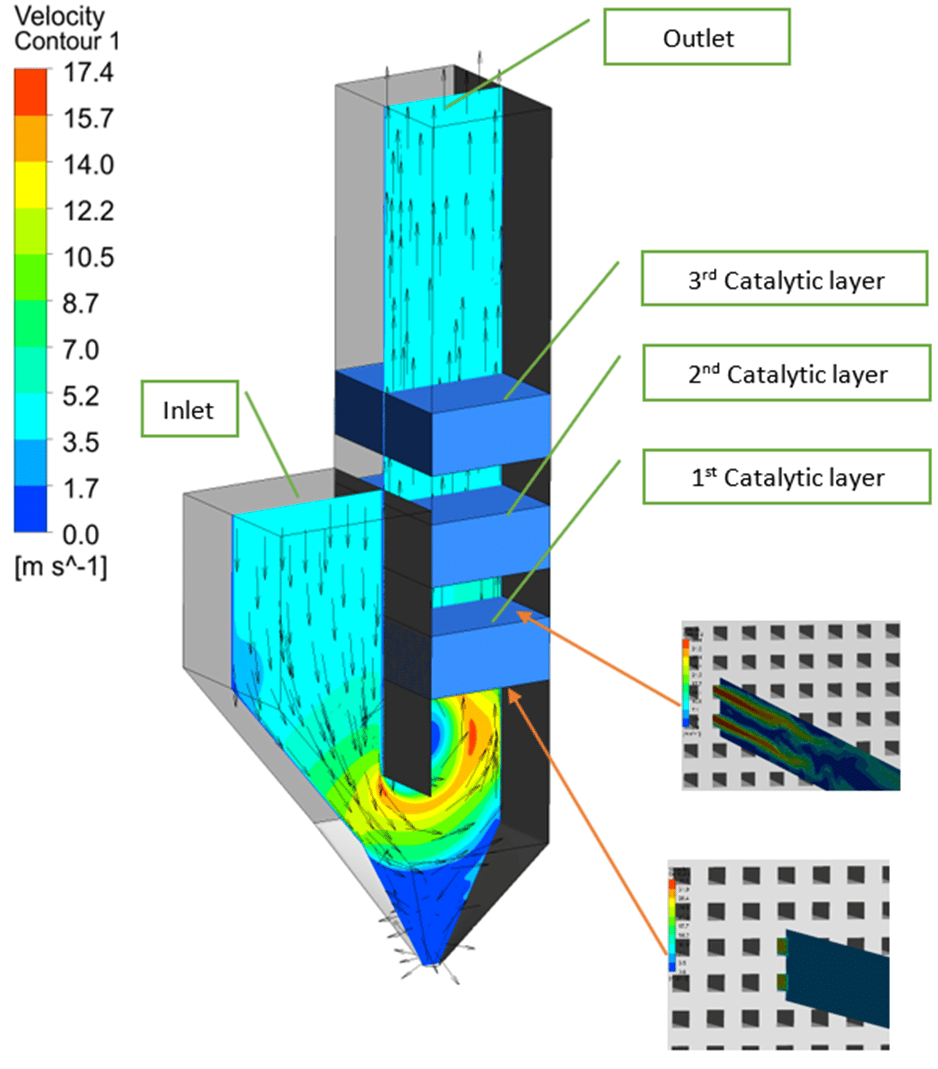

Numerical simulation of the SCR includes a problematic definition of inlet boundary conditions. As a source of boundary conditions can be used CFD simulation of combustion process or measured field data. SCR model was tested on the geometry of the coal combustion boiler and project design data specified by the catalyst manufacturer. The boiler is a waste incineration type and as a fuel is used municipal waste. The geometry of the combustion chamber part with catalyst was created according to drawing documentation. Results of CFD simulation were compared with task data. The main parameters were reduction of NO, pressure drop reduction of CO, and conversion of SO2 to SO3. The concentration of all species was calculated as an area-weighted average up and a downstream active catalytic layer or layers.

Benefits:

- confirmation of the applicability of CFD for SCR design and optimisation;

- time and costs saving due to speed up of SCR design process;

- environmental impact due to optimised SCR design leading to increase of NOx emission reduction.

SUCCESS STORY # HIGHLIGHTS:

- Keywords: Selective Catalytic Reduction (SCR), Computational Fluid Dynamics (CFD), High Performance Computing (HPC), Surface Chemical Reactions, NOx reduction,

- Industry sector: Energy, Environment

- Technology: HPC, Computational Fluid Dynamics (CFD)

Basic sketch of the test reactor

CFD simulation of SCR process

Contact:

Tomas Karasek (tomas.karasek@vsb.cz)

This project has received funding from the European High-Performance Computing Joint Undertaking (JU) under grant agreement No 951732. The JU receives support from the European Union’s Horizon 2020 research and innovation program and Germany, Bulgaria, Austria, Croatia, Cyprus, the Czech Republic, Denmark, Estonia, Finland, Greece, Hungary, Ireland, Italy, Lithuania, Latvia, Poland, Portugal, Romania, Slovenia, Spain, Sweden, the United Kingdom, France, the Netherlands, Belgium, Luxembourg, Slovakia, Norway, Switzerland, Turkey, Republic of North Macedonia, Iceland, Montenegro