NCC Türkiye presents two new success stories showing what results could be achieved by utilizing HPC technologies to tackle complex engineering problems. Below is a summary of successful use cases that have been conducted with the help of NCC Türkiye’s consultancy and infrastructure resources.

Enabling HPC Usage for Expensive ML Tasks on Manufacturing Environments

Erste Software is an SME focusing smart environments, and its main expertise is on Internet of Things and Big Data solutions.

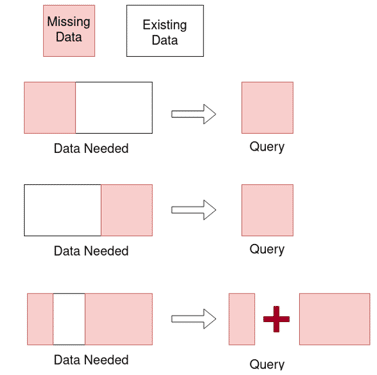

Erste is working on two international manufacturing projects. They require Anomaly Detection and Predictive Maintenance models trained on a huge amount of data. The company is highly fluent in front- and back-end development; the R&D team was developing prediction and classification algorithms to reduce the maintenance cost and downtime of the press machines used in production. However, in their use-case, the data can stream from up to 10 production lines, each having 3-10 machines, and each machine is equipped with sensors producing tens of data points in every milli-second.

Erste did not have any HPC skills or know-how on HPC clusters, SLURM, etc. This is why they have applied to the center. With the center’s consultancy and guidance, a solution that enables HPC usage is designed. Given a set of future tasks, the tool can automatically handle data movement, training, downloading models and deploying them back to the on-site server. At the end of the use case, Erste completed a proof-of-concept implementation of this module for their ML-based predictive-maintenance tool.

Training a medium-sized ML model on the server containing the streaming DB and answering the queries takes around 1 hour (on 8 cores) while no queries are being executed on it. With TRUBA’s high-end CPUs, the time reduces to around 30 minutes (on 8 cores) and with a single GPU, the training takes less than 10 minutes. Overall, the tool developed in this use-case allows Erste to keep the scarce on-site computational resources dedicated to their end-to-end Predictive Maintenance tool, basic data processing, e.g., rule-based anomaly detection on streaming data and data queries and leverage external HPC clusters.

End-user: Erste Software

Domain expert: Sabancı University

HPC infrastructure provider: TUBITAK ULAKBIM TRUBA HPC Center

Success story details: http://eurocc.truba.gov.tr/?page_id=6834&lang=en

Keywords: Offloading, streaming data, manufacturing & engineering, HPC, AI, ML.

Code Modernization for the Glass Industry

As one of the most powerful industrial conglomerates in Türkiye, Sisecam is a global player in all key areas of the glass industry. It is currently one of the world’s leading glass producers with production operations located in 14 countries on four continents, 24000 employees, and sales in over 150 countries around the globe.

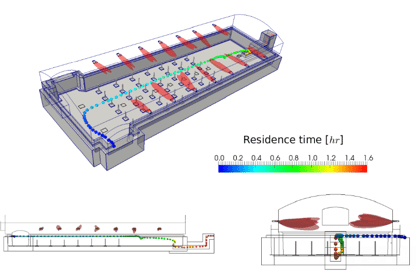

Şişecam fabricates glass products using custom-made furnaces. They use a simulation code written some decades ago that traces the glass particles inside the furnace. In a nutshell, the longer the particles stay inside the furnace, the better the quality of the product. Before the use-case study, the simulation process was taking days and Şişecam was limited by small models to make the process faster and wanted to increase the size to have more accurate simulations. The NCC helped Şişecam engineers to convert the code to a more modern architecture and discuss/recommend parallelization strategies on a multicore system with OpenMP. At last, the Fortran code is translated to modern C++ line by line, except goto statements which are translated as loop constructs for better readability. Then, the dead code is eliminated to reduce code size. Common logical patterns are converted to functions for better readability.

On the longest-running test case provided by Şişecam, the Fortran code was taking 7 hours 14 minutes on the development machine, whereas unoptimized C++ code takes only 27 minutes 21 seconds. On a server with 20-core Xeon 6148 2.40 GHz, the code only takes 286 seconds. Even when a single thread, the runtime is 18 minutes, a huge speed-up compared to 7 hours on the development machine. Using 20 cores, the new implementation was able to achieve 3.86x speedup which can be further improved.

End-user: Şişecam

Domain expert: Sabancı University

HPC infrastructure provider: TUBITAK ULAKBIM TRUBA HPC Center

Success story details: http://eurocc.truba.gov.tr/?page_id=6839&lang=en

Keywords: Glass production, particle simulation, code modernization, glass manufacturing & engineering, OpenMP.